A Step Beyond Your Expectations:

50th Anniversary

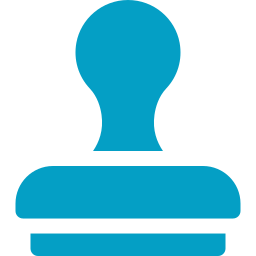

In the early years beginning in 1973, brothers Henk and Marinus Noordermeer ran their machine shop out of a family garage. Machining and welding work came from mostly local farmers and manufacturing facilities in the London and Strathroy area. As work overpowered the garage-based shop, the brothers went looking for a location to build a shop and hire new employees.

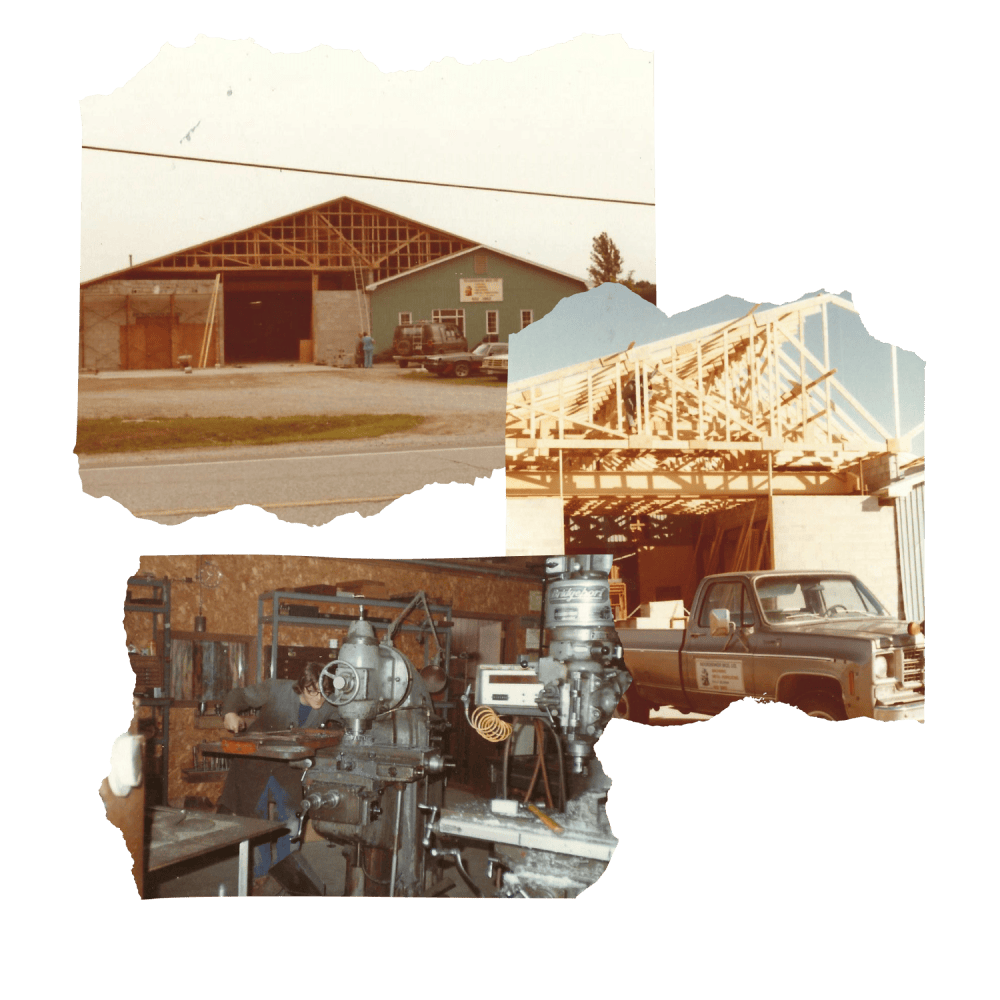

Delaware, Ontario was selected and in 1974 a new plant was built. Equipment on the shop floor at the time included manual machinery including milling machines, lathes, welding and grinding. Equipment expansion followed, and during this process the highest quality state of the art machines were selected, including 3-axis milling machinery in the form of Bridgeport milling machines of the knee and column base configuration. This was required to facilitate the millwright, and machining work contracted to them by large manufacturing plants and other local factories in the London area.

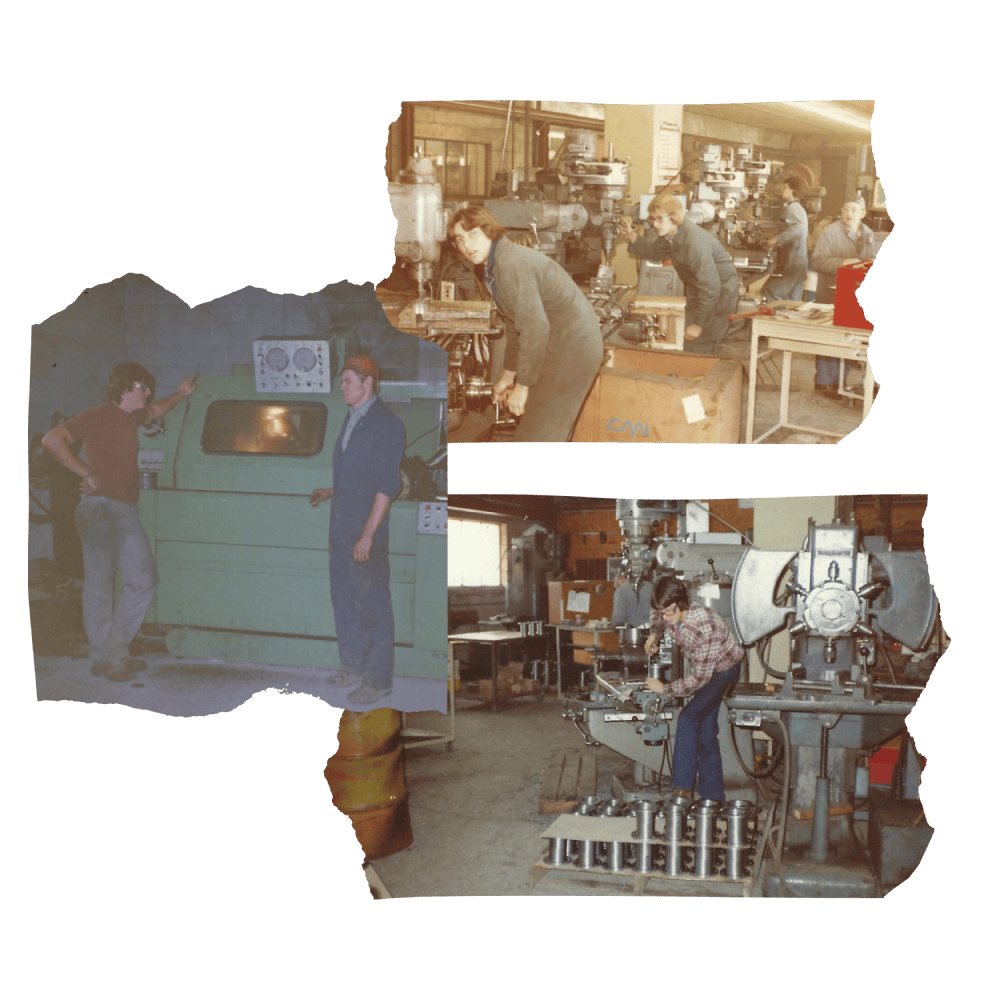

In the late 70s and early 80s, Noordermeer transitioned out of the Millwright work and concentrated on high precision machining and fabrication work from a number of factories in Ontario and the USA. It was then that they added their first state of the art CNC (computerized numerical control) Cincinnati Lathe, followed by a CNC Burgmaster vertical milling machine with a 31-tool turret. The digital revolution took seat quickly at Noordermeer as advanced programming software facilitated the operation of CNC machinery.

To accommodate the digital revolution, the original shop was expanded three times to its present day 25,000 square feet. Storage was moved outside which freed up valuable shop floor space to add even larger CNC mills and lathes. In 1997 a major investment was made in an Okuma MX60 Horizontal Machining Center. Then in 2007, the NT-4250 was purchased, requiring serious construction work to isolate the chassis from shop vibration with a four-foot-deep cement footing to maintain absolute accuracy of the double chuck lathe/mill with tolerances of 0.0001”

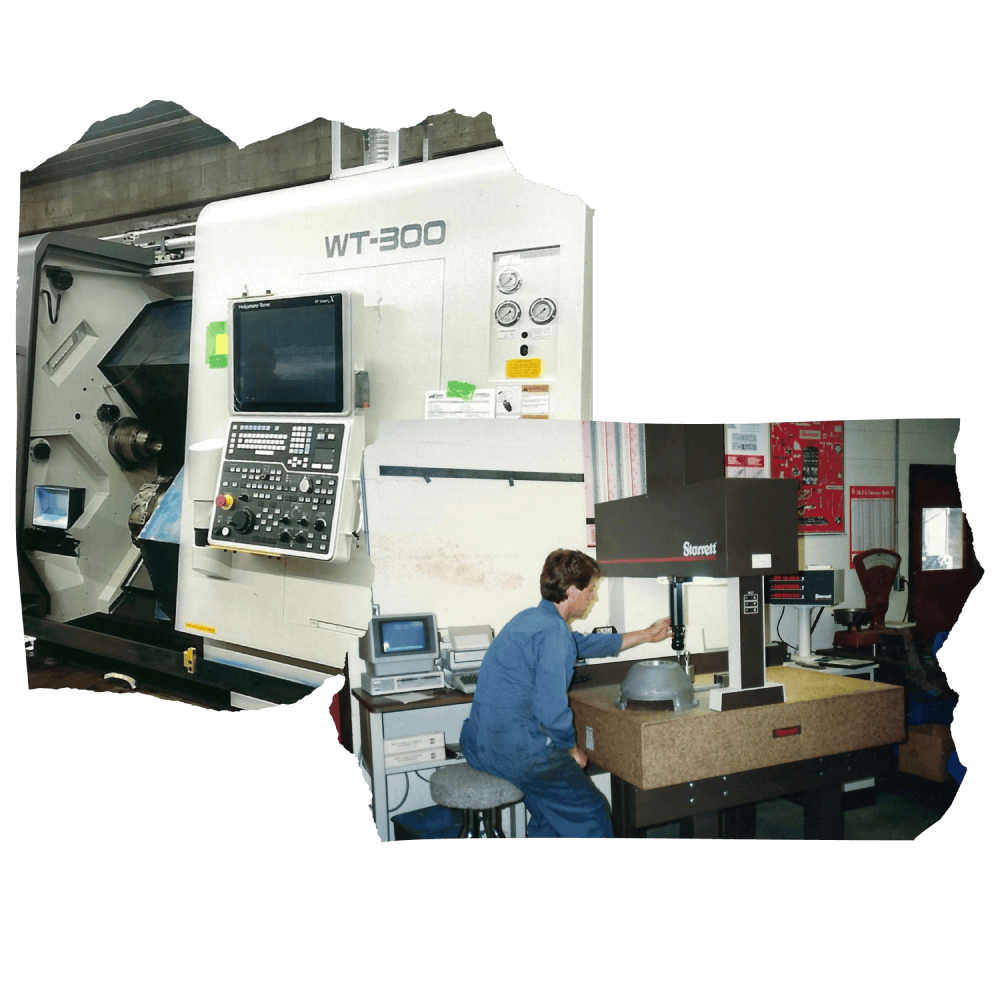

The digital evolution continues today with the Nakamura Tome WT-300 Mill/Turn machine in 2022 along with a 12 ft Hydraulic CNC Brake in 2023. Over the years the CNC equipment on the shop floor has been in a constant upgrading process as faster, more accurate machines become available.

Fast forward 50-years from the garage and the originating brothers Marinus who is retired, and Henk who continues to come to work every day, looks back with pride at what has been built. Henk’s sons have since taken over the everyday operations at Noordermeer Bros Inc. and the same principles that built the business then are being used today. With the many long-term staff employed, and an eagerness to stay ahead of technological advances in digital machinery, the delivery of high quality, agile and fair pricing for Noordermeer’s customers is realized.